Despite my best efforts, my TV setup has 5 remotes. 99% of the time you just need the main TV remote, but sometimes you need to turn on the fan or set the speakers to Bluetooth mode or something, then you need one of the other guys.

I mulled many, many perfectly fine solutions to this very easy problem, and rejected all of them for not being perfect. You see, I wanted a system that would:

- let me reorganize the remotes as things changed,

- not make me have to drill new holes in the side table every time,

- not rely on adhesives,

- feel rigid (ruling out command strips, velcro, and dual-lock), and

- hold the remotes tightly together.

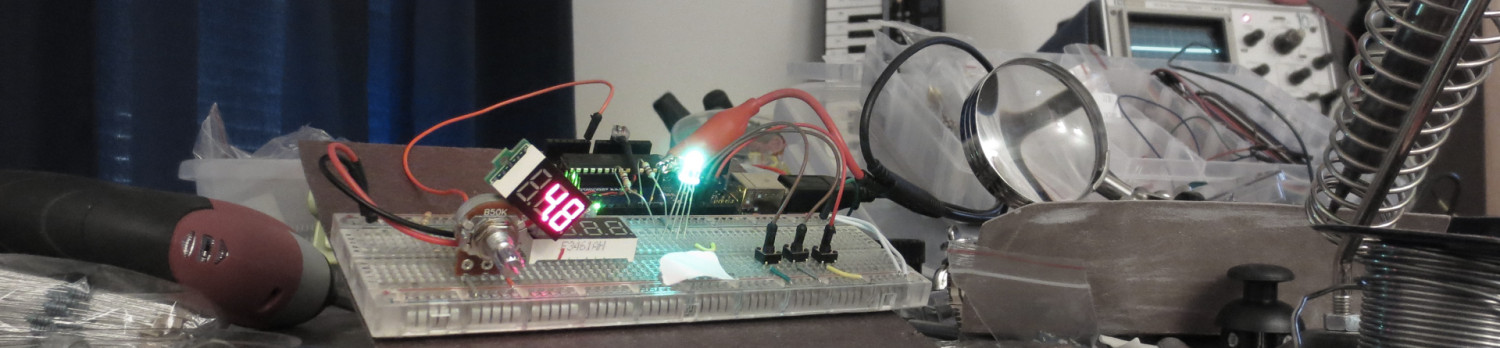

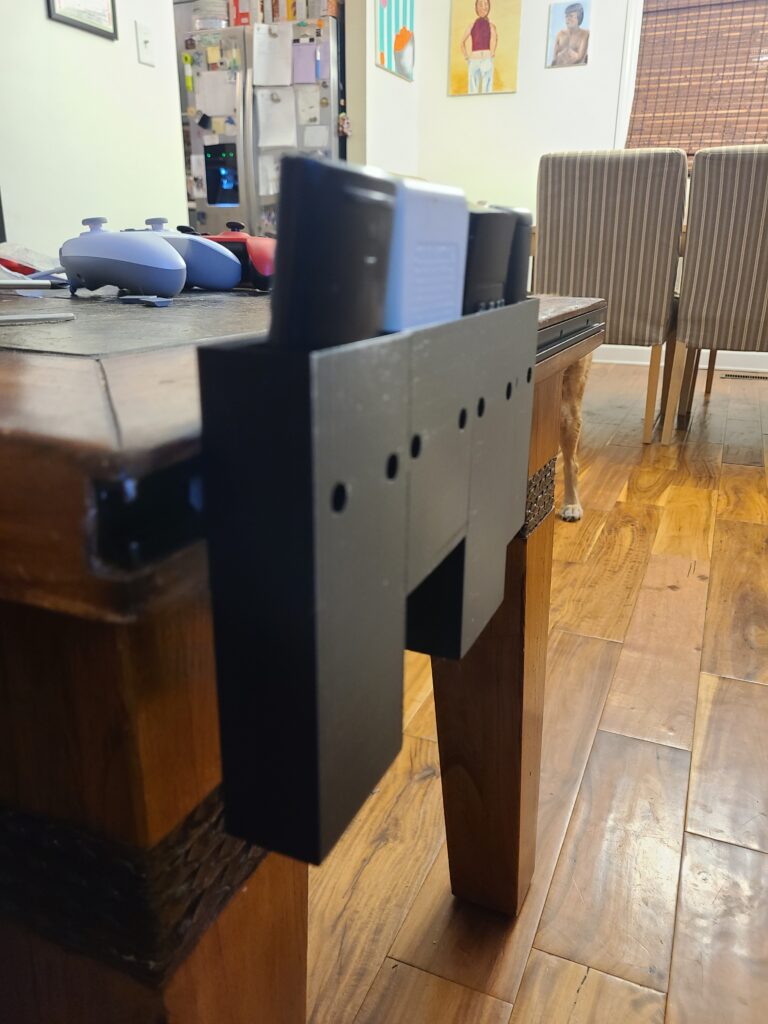

What I arrived at is based on 2ft of black aluminum T-track rail, the kind you’d have in a router table or something to hold a fence or work piece down. I got a cheap router from a thrift shop, and routed a channel into the existing side table, which is beefy wood and stone. I ran a little wood stain down the channel so there wouldn’t be any off-putting white wood peeking out, then screwed in the rail, fitting snug and flush.

The remote holders are 3D printed and have countersunk holes for M3 screws, with some some access holes in front to fit the screwdriver. They accept 3D printed T-nuts with captured hex nuts, then slide down the rail to where ever you want, getting tightened down to a satisfyingly rigid hold.

The CAD model (available here) is parametric and configured for the exact dimensions of each remote, so they all stick up to the exact same height, making for pleasing, easy access:

It’s real good. The end.