NOTE: Everything involved in this post is available for download here.

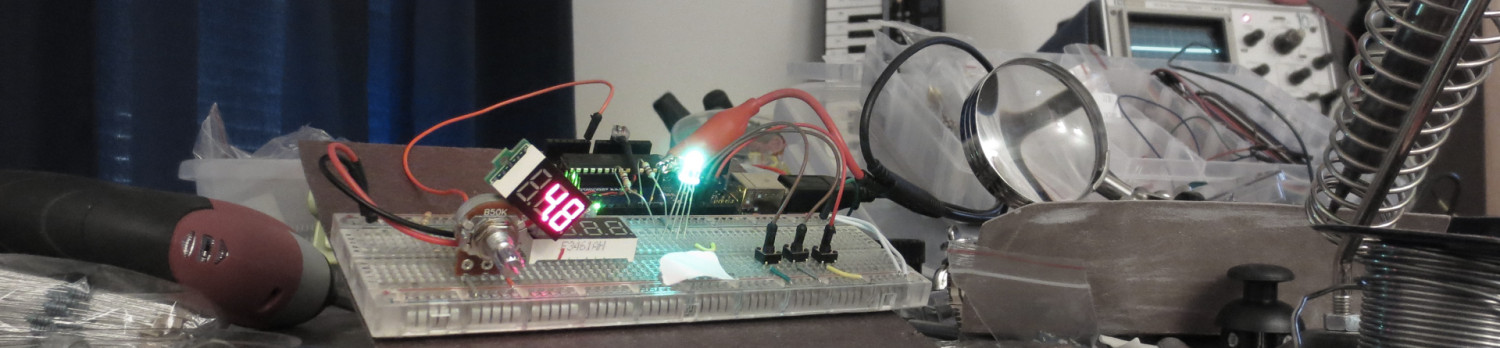

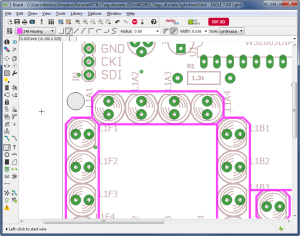

I while back, I made this PCB that acts as a big daisy-chainable two-digit 7-segment display using the WS2803D and discrete LEDs. The pic to the right is a shot of the first use of these PCBs: a big sign that says “4561”.

I while back, I made this PCB that acts as a big daisy-chainable two-digit 7-segment display using the WS2803D and discrete LEDs. The pic to the right is a shot of the first use of these PCBs: a big sign that says “4561”.

It works great, interfaces easily with AVR/Arduinos, and is cheap to build.

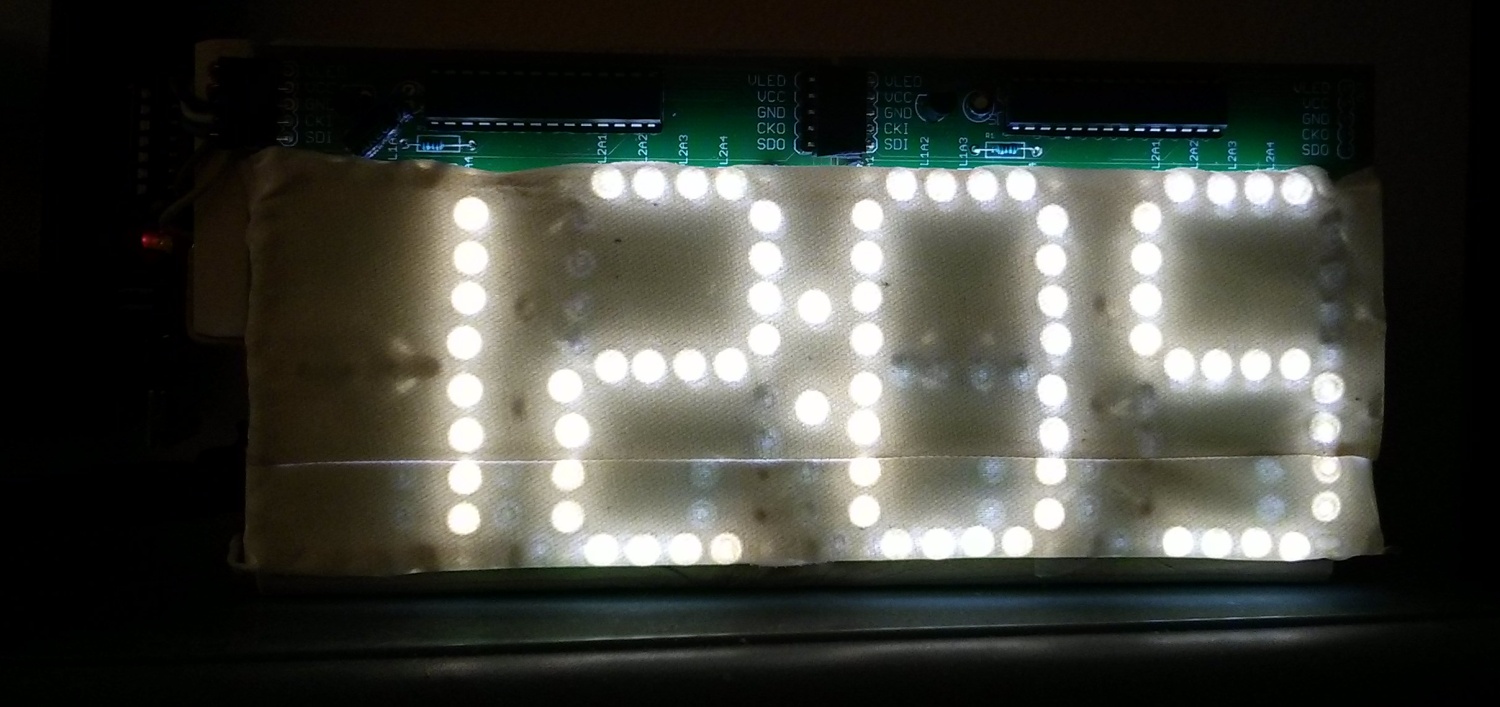

One thing that’s not great about it is the amount of light leakage from the LEDs — if you put some kind of light diffuser in front of it, you see all kinds of reflected and refracted bits of light. Here’s a shot of a clock I made out of these boards with white gaffer tape as a diffuser:

Look at all those random patterns of light…it’s shameful.

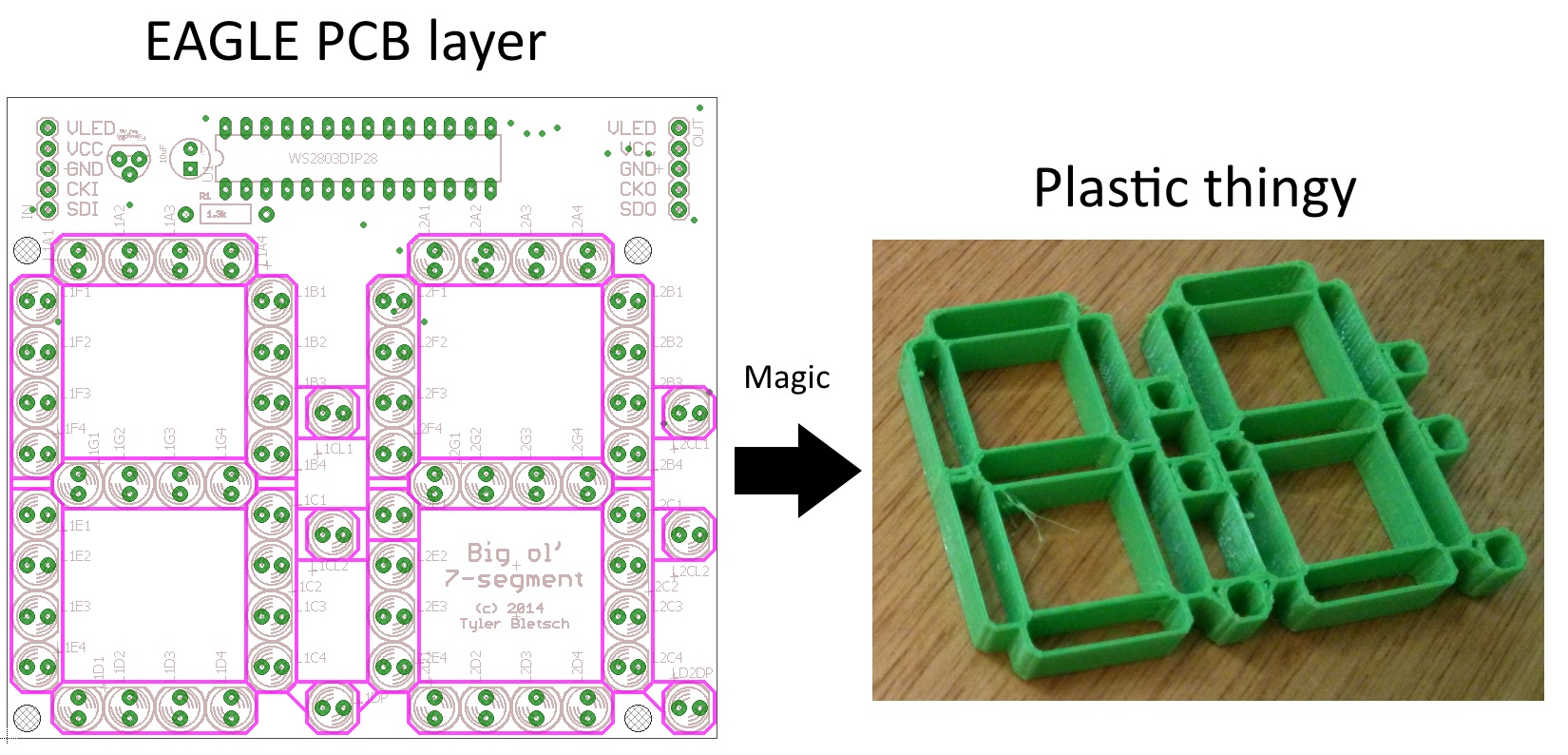

Today I figured out a simple way to 3D print a light mask for this board using design elements straight out of EAGLE! Here are the high-level steps:

- In a new layer in your EAGLE board layout, draw the stuff you want to 3D print.

- Do a series of conversions to get that EAGLE layer turned into an OpenSCAD script and then a STL for printing.

- Print, jam on board, enjoy a better looking display.

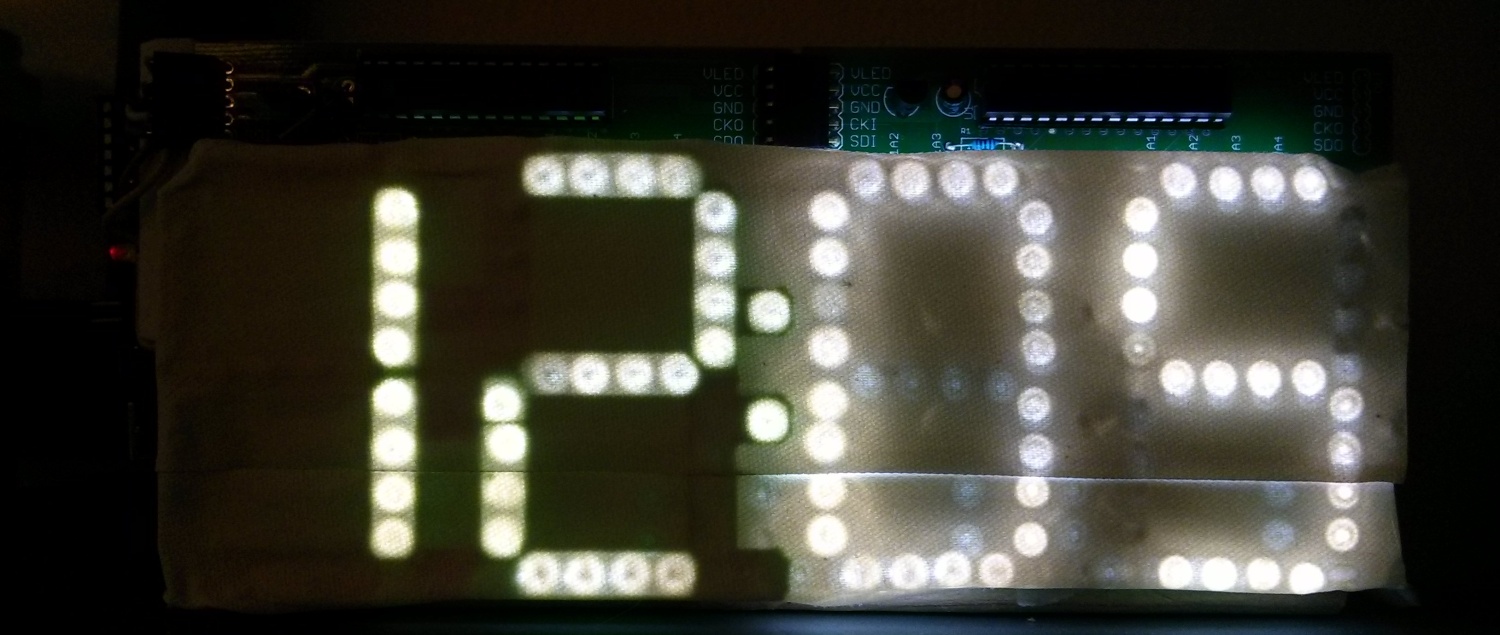

Here’s a shot of the light mask applied to the left two digits of the clock:

Full directions after the break.

EAGLE is of course a 2D program, and we want to make a 3D thing. However, the thing in question is just a 2D form extruded into 3D, so we can actually draw the thing in EAGLE, then just say how tall it needs to be later. You’ll need three programs:

- EAGLE

- Inkscape

- OpenSCAD

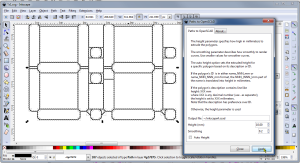

- Draw whatever crap you want 3D printed on a separate EAGLE layer. I used the “Housing” layer (248).

- In the CAM processor:

- Select only the relevant layer

- Device = EPS

- Scale = 1

- File = “%N.eps” or whatever

- Click “Process Job”

This gives us an EPS file (a form of PostScript) with the 2D figure. Next, we use Inkscape to turn this into an OpenSCAD 3D design.

- Install paths2openscad. Download and extract to “%APPDATA%\inkscape\extensions” (Windows) or “~/.config/inkscape/extensions” (Linux/Mac).

- (Re)start Inkscape

- Drag the EPS file in, accept the default import settings

- Right click the thing and choose “enter group”

- Press Ctrl+A to select all pieces — they should all highlight separately.

- From the Path menu, select Stroke to Path. It will think a bit to turn all those lines (which are 1D strokes with thickness) into paths (which are true 2D forms).

- From the Extensions menu, select “Generate from Path” > “Paths to OpenSCAD”. Accept the defaults, setting height as you see fit. Export the OpenSCAD file.

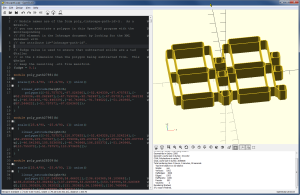

Now we have an OpenSCAD script.

- Load the thing

- Render the thing

- Export as STL

Then just 3D print it up! For this particular thing, I set my line width in EAGLE to 0.016″ (~0.4mm), which is the size of my 3D printer’s nozzle. That meant that every line was a single pass of the printer.

What doesn’t work

I thought I’d vent for a bit on the many, many ways of doing this that did not work:

- EAGLE can export a DXF file, and OpenSCAD supports import of DXF, so you might think you can skip the whole Inkscape nonsense. Not so — EAGLE uses DXF commands that OpenSCAD doesn’t understand.

- Similarly, Inkscape’s DXF import also chokes on EAGLE DXF files.

- You might think you could somehow post-process the DXF into a more normal format and extrude it using another CAD package. This is probably possible somehow, but all the toolchains I tried failed at one point or another.

- Converting DXF using QCAD didn’t work, despite QCAD supporting like 20 flavors of DXF.

- Converting from DXF to SVG using QCAD worked, but then my “trial” of that feature expired, as if exporting to SVG is worth 33 freakin Euros.

- You can do QCAD DXF import -> QCAD PDF export -> Inkscape import, but it’s long and awkward, especially with QCAD’s weird handling of units.

- Many 3D CAD packages’ attempts to load the DXF would turn it into a pile of rods, ignoring the whole “lines that make up the shape” aspect. I’m looking at you, TinkerCAD.

- Online web-based format converters often butchered the form entirely.

- I tried to use Blender HAHAHAHAHAHA what a nightmare.

- FreeCAD is a literal warcrime.

Pingback: Fitting 3D Prints On Eagle Boards | Hackaday

Really nice work